- 55 , Milestone, Nh-73, Panchkula Road, Saha, AMBALA, Haryana, India 133104

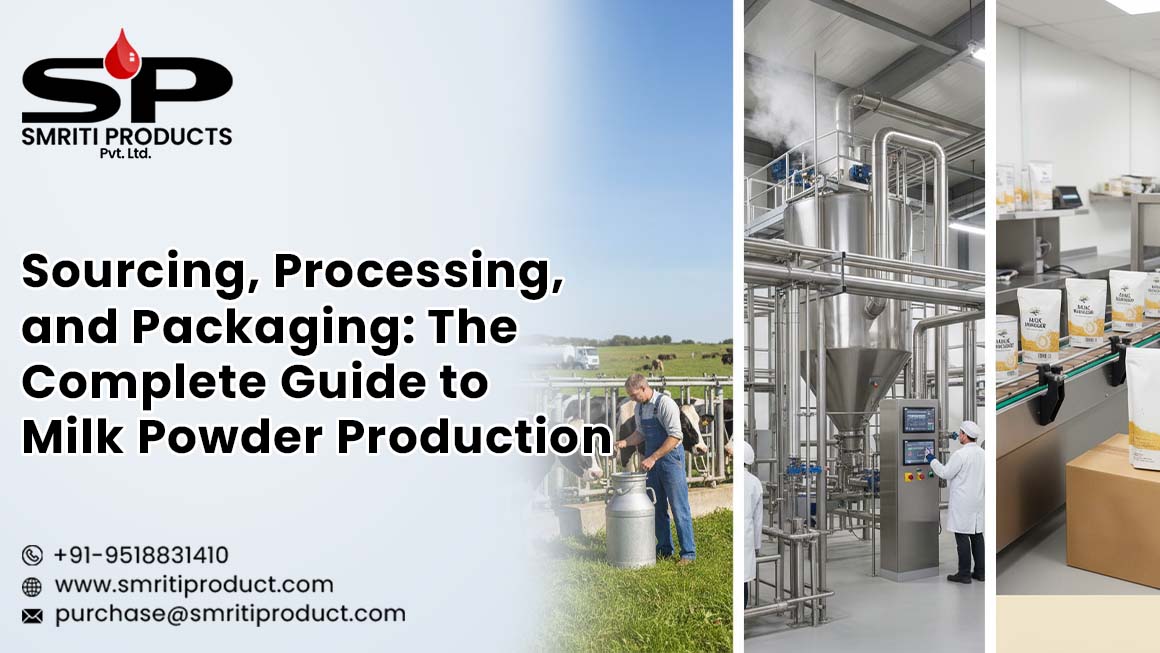

Fresh milk is a household commodity in many places around the globe and transforming fresh milk to a long-lasting and stable commodity needs skills and accuracy. Milk Powder Producers in India have mastered this process and the consumers receive high quality milk powder that preserves the taste, nutrition and safety.

Since fresh milk may be sourced, to the high-level packaging equipment, producers incorporate science, technology as well as quality management in order to come up with a product that has reached both local and global standards.

In this blog we will discuss about every step from collecting fresh milk to finally packaging of milk powder.

The quality of milk powder is initiated by the raw material fresh milk. Producers focus on:

The sourcing phase predefines the whole production process where only the finest milk passes into the production line.

The processing of milk is an art of science. Key steps include:

Milk Powder Producers use modern technology which guarantees consistency in texture, taste and solubility of powdered milk and ensures quality, which is not compromised.

Packaging is not merely a container but it maintains quality and provides safety. Key practices include:

Effective packaging means that the powdered milk can be supplied to the consumers in the most optimum state even after a long storage or transportation distance.

Innovation is significant in preserving milk powder in a fresh, safe and nutritious state over longer periods of time. The modern milk powder manufacturers employ sophisticated drying techniques that dry the powder evenly and this makes it less likely to develop bacteria.

Such smart packages as airtight pouches or nitrogen flushing help inhibit oxidation and contamination during storage and transportation. Quality sensors and automated tools will also help in identifying any form in the temperature or humidity during the process.

Milk packaged powder is a complicated process that involves accuracy, technological advancement, and quality assurance of milk. Companies like Smriti Products are the best Milk Powder Producers in India make sure that the complete process- sourcing fresh milk to high-end processing and safe packaging is done in a manner that would satisfy the global standards and provide a product that is nutritious, safe and convenient.

Continue to Chat